It is similar to my air gun obsession, in that there are many levels. Why just shoot air guns when you can tune and mod them. Why just play a CBG when you can build them?

Besides building guitars there are Amplifiers to build, I have a background in electronics so this part of the hobby is going to require less work than trying to relearn how to play a guitar.

I purchased an amplifier kit that is based on the LM386 OP amp. It is a bare bones kit without any switches or a speaker.

The kit came with a schematic and some notes about options for the amplifier circuit.

I had a cigar box that wasn't going to work for a guitar but would make a great housing for my amp.

A $1 pawn shop speaker should work for this amp.

I dug out my 1980s vintage soldering iron, solder and flux.

Let the soldering begin....

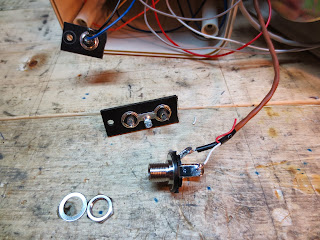

I decided to wire the 1/4" jack and speaker directly to the board instead of using the supplied jacks.

I added a remote pot for the volume control instead of the miniature board mounted pot that came with the kit. I also added a switch to turn the power off and on.

A plate was added to the box to hold the input jack and volume control. I didn't want to ruin the logo on the front of the box so I cut a hole in the back for the speaker and I mounted the power switch on the side.

With everything mounted, (except the battery) I took the amp for a test drive.

It wont make your ears bleed, but I was surprised how much sound it puts out. With the Licence plate guitar and its piezo pick ups it puts out a nice clean sound. When I plugged in my Peavey electric guitar it put out plenty of volume and had some nice crunchy distortion.

I'm pleasantly surprised with how this amp turned out and the amount of sound that an amp powered by a 9 volt battery will put out.